Raw magnets

Raw magnets are all magnets that consist of pure magnetic alloy. These are permanent magnets made of the alloy neodymium-iron-boron (NdFeB), samarium-cobalt (SmCo), aluminium-nickel-cobalt (AlNiCo) or hard magnetic ferrites (HF), which are mainly produced by sintering or casting. In some cases, galvanic coatings are necessary for continuous use.

Raw magnets of Neodymium-iron-boron (NdFeB)

Raw magnets of Samarium-Cobalt (SmCo)

Raw magnets of hard ferrite

Raw magnets of Aluminum-nickel-cobalt (AlNiCo)

Our large selection of raw magnets for a specific application!

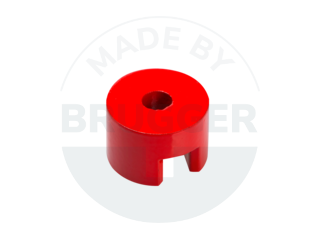

A raw magnet is usually a starting product, a base that is used for various applications in combination with another component. Raw magnets are suitable for building specific magnet systems when no suitable standard magnet systems can be used. We have a wide range of raw magnets in various materials and in different shapes (disc, cylinder, cuboid, ring).

Hard f errite magnets (HF) consist of magnetisable ferrite and are very favourably priced permanent magnets. They are known as hard ferrite magnets, ceramic magnets or ceramic permanent magnets. The advantage of magnets made of ferrite is that the magnets last a long time even under extreme conditions, do not lose their static magnetic field and are also not susceptible to chemicals, alkalis and salts.

Neodymium-iron-boron magnet s (NdFeB) are the strongest of all permanent magnets. Due to their immensely high magnetic strength, NdFeB magnets are the first choice for industry and technical applications. Neodymium magnets, also called NdFeB, Neo or ReFeB magnets, are the strongest magnets in the world and are also called super magnets; they have the highest magnetic properties of all permanent magnets. Even with small dimensions, neodymium magnets can hold many times their own weight and prove their strong holding power.

AlNiCo magnets consist of a metallic alloy of aluminium, nickel, cobalt as well as iron, copper and titanium. It is the oldest permanent magnetic material still in use. The main advantages of the AlNiCo magnet are its suitability for use at temperatures from -270°C to 550° C and its good machinability.

Samarium-cobalt magnets (SmCo) are more expensive than other magnet materials due to their high cobalt content. SmCo magnets oxidise only slightly and have good chemical resistance. Due to their high energy density (approx. 30-40% less than NdFeB magnets), high holding forces can be achieved. They can be used in temperature ranges from -40°C to +350°C.

Application examples:

- Basis for the production of individual magnet systems

- As a closure or form closure for folders, sleeves and covers

- For switching electrical components

- For determining the position of components