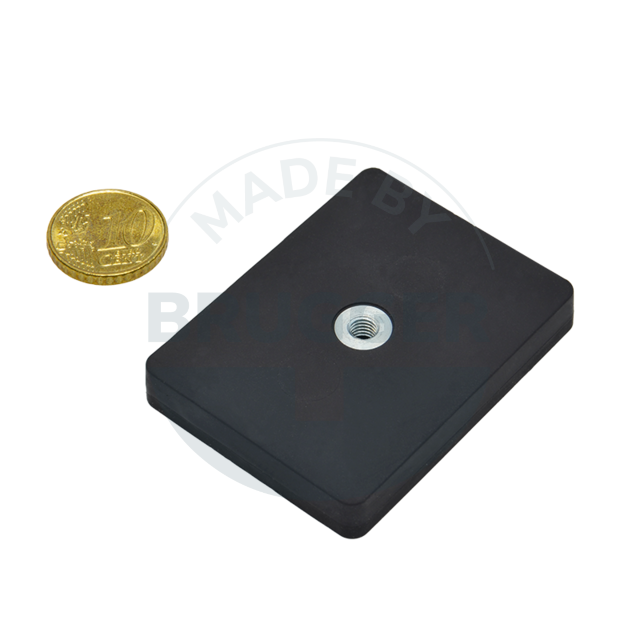

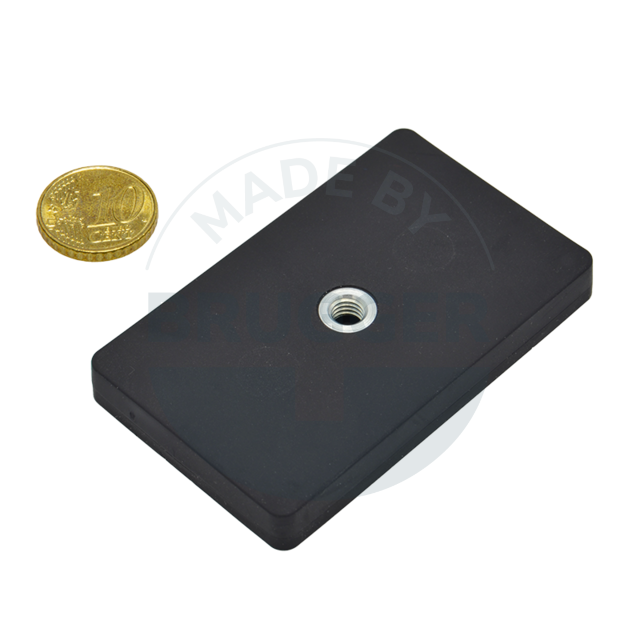

Rubber coated systems

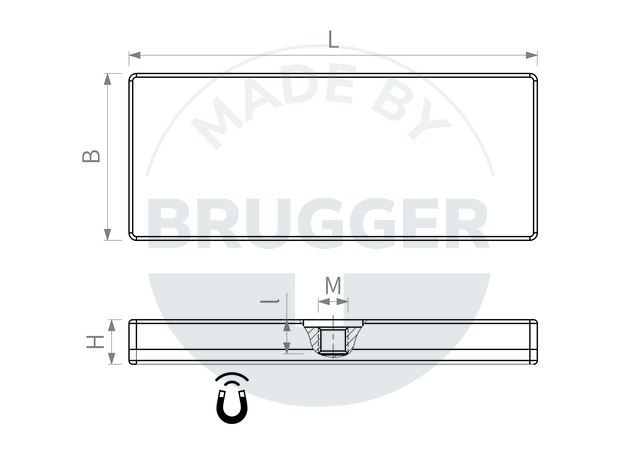

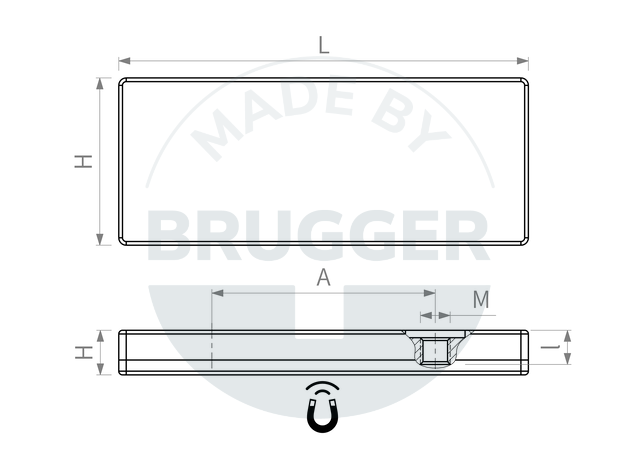

NdFeB magnetic system, black rubber sheath, with internal thread, rectangular

Rubber-coated magnetic systems are real all-rounders and can be found in many areas. The systems are particularly suitable for use on sensitive surfaces, thin sheet metal or vertical applications. They can also be used outdoors. In contrast to the round magnetic systems, these systems can be positioned with a positive fit. In addition, variants with double threads can be mounted without twisting and supplemented with many standard parts.

PRODUCT INFORMATION:

These items have a special rubber coating made of TPE (thermoplastic elastomer). There are no scratches or discolouration on the surface. The displacement forces and corrosion resistance are also higher due to the rubber coating. A small side effect is also the noise-reducing effect when putting it on. There are strong neodymium magnets inside, which generate a large and strong magnetic field due to their arrangement and in conjunction with the metal element inside. At the same time, the internal metal element shields the magnetic field on the back and also ensures that, unlike with pot systems, the magnetic field has a deeper effect and can bridge larger gaps.

As an alternative to the standard system, we also offer customised solutions:

" Other colours for the rubber coating

" Harder or softer rubber coating

" Higher adhesive force

* The forces have been determined at room temperature on a polished plate made of steel (S235JR according to DIN 10 025) with a thickness of 10 mm (1kg~10N). A deviation of up to -10% from the specified value is possible in exceptional cases. In general, the value is exceeded. The type of application (installation situation, temperatures, counter anchors, etc.) sometimes influence the forces enormously. The values given are for orientation purposes. Let our experts advise you.