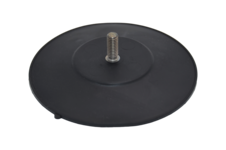

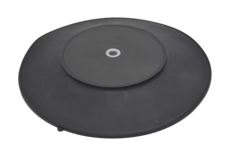

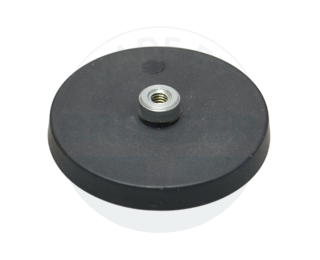

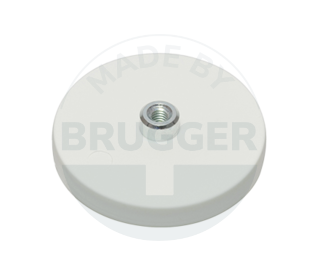

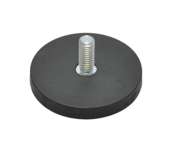

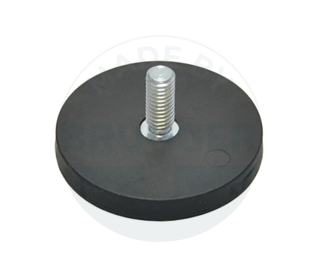

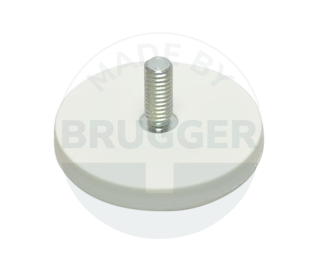

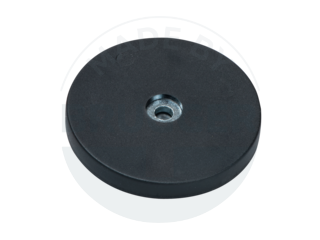

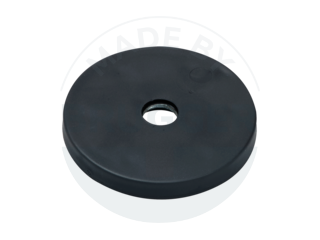

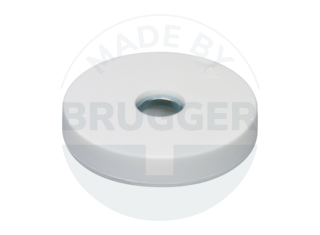

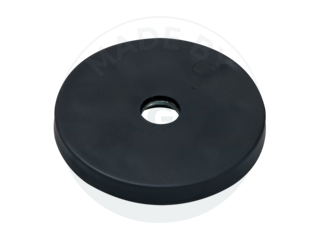

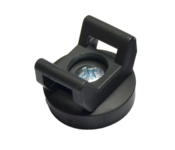

Rubberised magnet systems

Rubberised magnet systems are those magnet systems that are overmoulded on all sides with a rubber-like plastic (TPE). Rubberised magnet systems are used especially where sensitive surfaces, design or high displacement forces are involved.

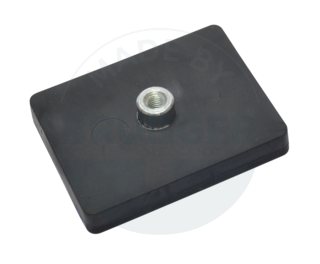

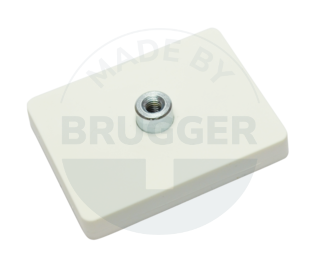

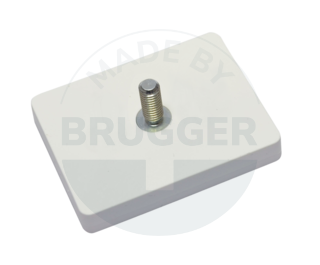

Rubber coated systems

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

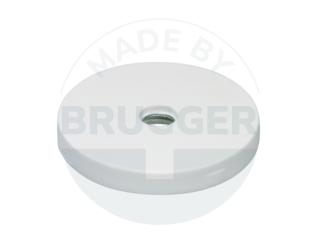

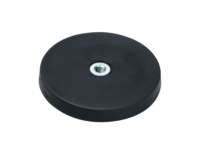

Our rubberised magnet systems for sensitive surfaces!

Rubber-sheathed magnet systems are real all-rounders and can be used in many areas. The systems are particularly suitable for use on sensitive surfaces. In the standard range, these are available in eight different diameters between 12 and 88mm with both white and black rubber jackets. We cover adhesive forces between 1 and 55kg. Due to the special rubber coating, there are neither scratches nor discolouration on the surface. In addition, the displacement forces and the corrosion resistance are higher due to the rubber coating. A small side effect is also the noise-reducing effect of the rubber coating when putting it on. Inside, there are strong neodymium magnets which, due to their arrangement and in combination with the metal element inside, generate a large and strong magnetic field. At the same time, the metal element inside shields the magnetic field on the back and also ensures that - unlike pot systems - the magnetic field has a deeper effect and can bridge larger gaps. M4, M6 or M8 threaded sockets are used for mounting. All systems are REACH and RoHS compliant and free of harmful plasticisers. Black magnet systems with rubber coating are UV-resistant.

Application examples:

- Fastening cables and lines to wind turbine towers

- Fastening of cables and wires to machines and plants

- Fixing of signal lights or signs on vehicles

- Fixing of films for vehicle wrapping (car wrapping)