Magnetic systems in the food industry

Magnetic solutions for metal separation in the food industry: For quality with safety

In few other industrial sectors is the purity of contaminants, germs and other foreign bodies as important as in the food industry. A lack of cleanliness throughout the entire production chain is not only associated with health risks for consumers. They can also cause considerable economic damage to manufacturing companies. It is therefore important to install a fundamental and consistent safety management system. Magnetic systems from Brugger are an important part of this.

Where can magnetic systems ensure safety in food production?

Magnetic systems are used in the food industry in particular where metallic contaminants are involved. This applies in particular to unwanted metal particles in food production. For example, metal contamination (from large parts such as screws to the smallest chips) and bacterial growth in product channels or pipework or foreign bodies in the form of metal contaminants. These can enter the food production chain in various ways:

-

Entry of contaminated material

-

Machine wear and tear

-

Maintenance of the production line

These metallic contaminants can have very serious consequences: In addition to machine damage and production downtime, they also include contaminated products and product rejects, associated with health risks for consumers and possible claims for damages. With our magnetic systems, we at Brugger support food manufacturers in eliminating metallic contaminants and thus ensuring food safety and quality.

Which magnet systems are particularly suitable for the food industry?

As already described, magnets and magnet systems are particularly suitable for detecting and removing metallic contaminants in food production processes. Two solutions are particularly suitable here:

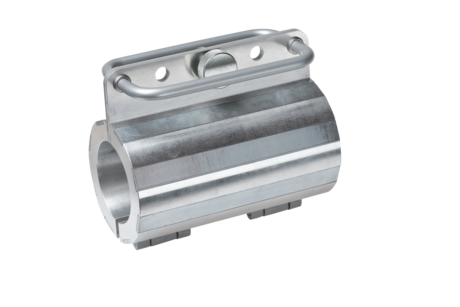

- Magnetic filter rods have been specially developed for the food industry. The neodymium magnetic rods are extremely strong and effectively remove small ferromagnetic contaminants from the mass flows in pipework. With our strongest types, even the finest, weakly magnetic impurities, such as wear particles, can be removed. Magnetic filter bars are the basis of many magnetic separators, such as magnetic grids, cleanflow magnets and magnetic filters for pressurised lines.

-

Magnetic filter grids (or magnetic filter grids) are placed at important points, such as a feed point or collection hopper, to filter the finest magnetic and even weakly magnetic ferrous contaminants from free-flowing powders and granulates. Our magnetic filters are equipped with a control function and thus ensure reliable and efficient cleaning of the material. With our magnetic filters, we help to make food production safer and of higher quality.

In concrete terms - magnetic systems from Brugger are used in food production for

-

filtering metal particles from liquids

-

filtering metallic contaminants from and on feed systems

-

filtering particles from dry foodstuffs