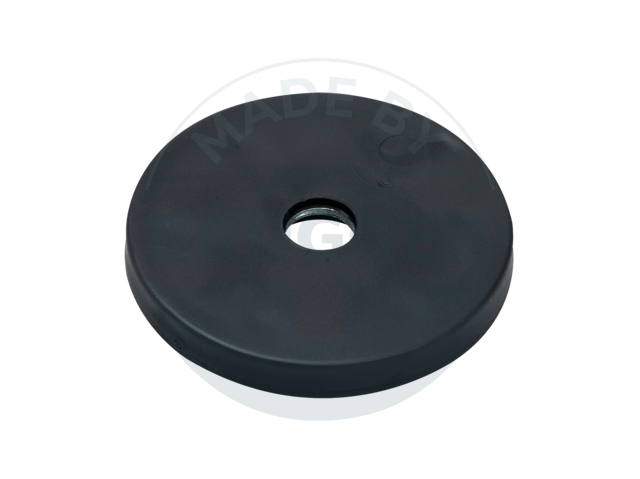

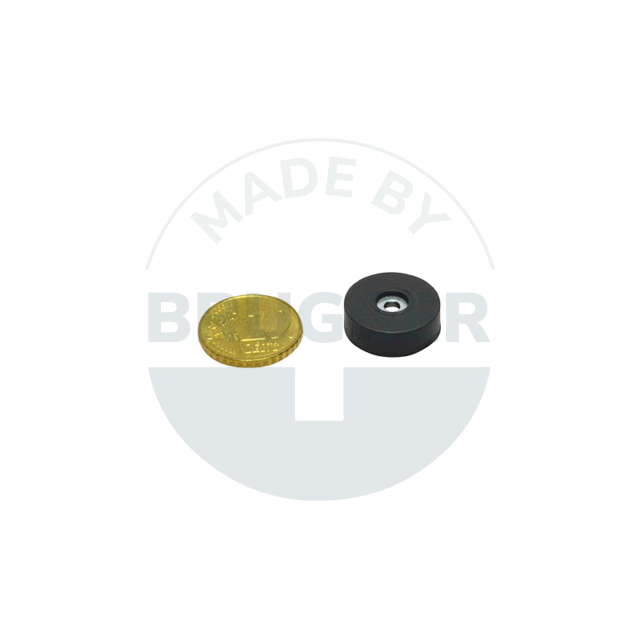

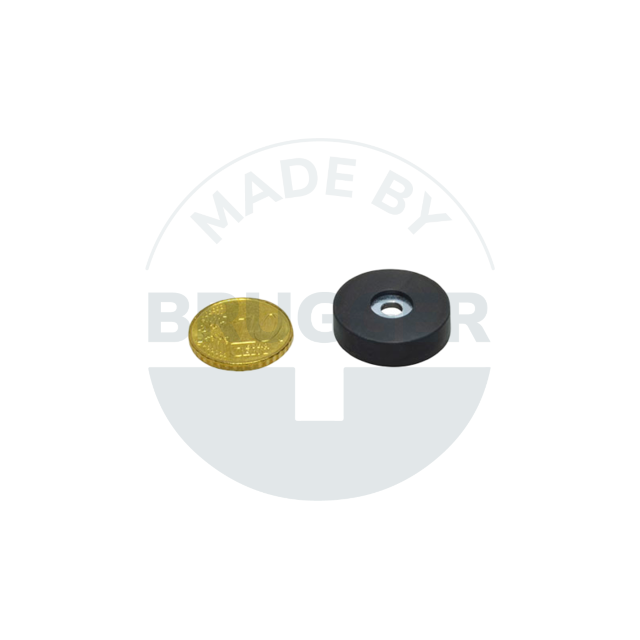

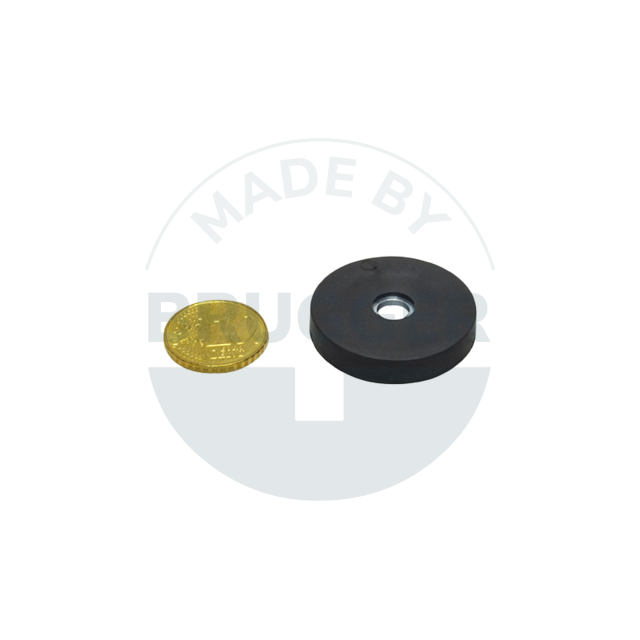

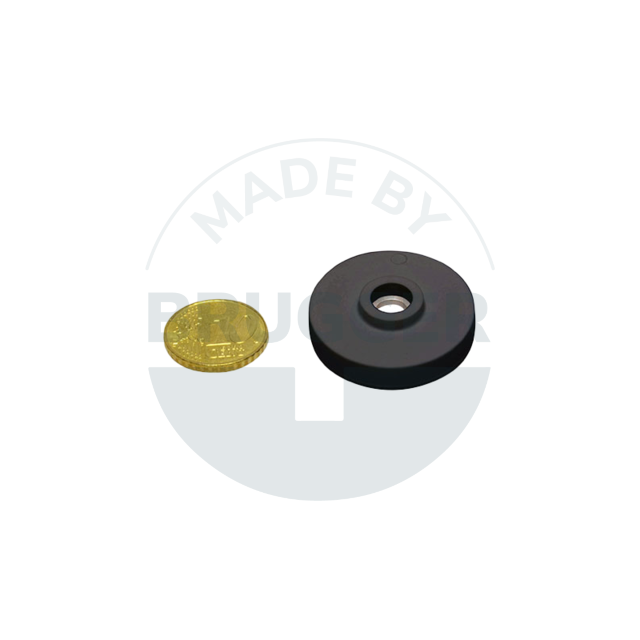

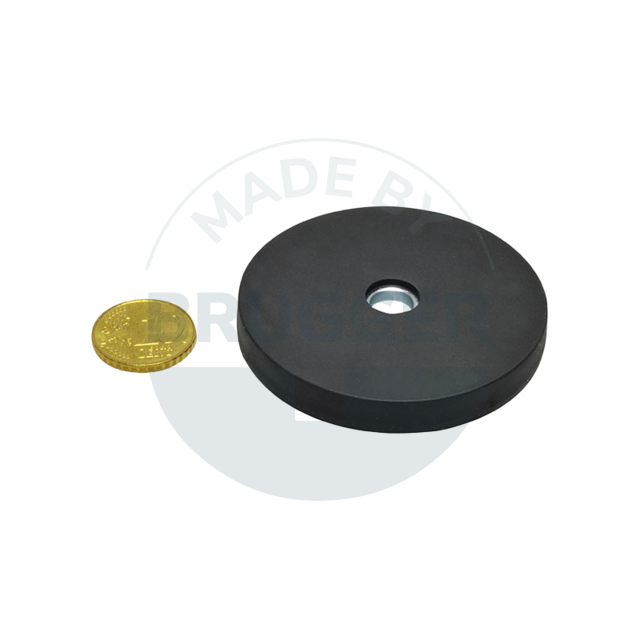

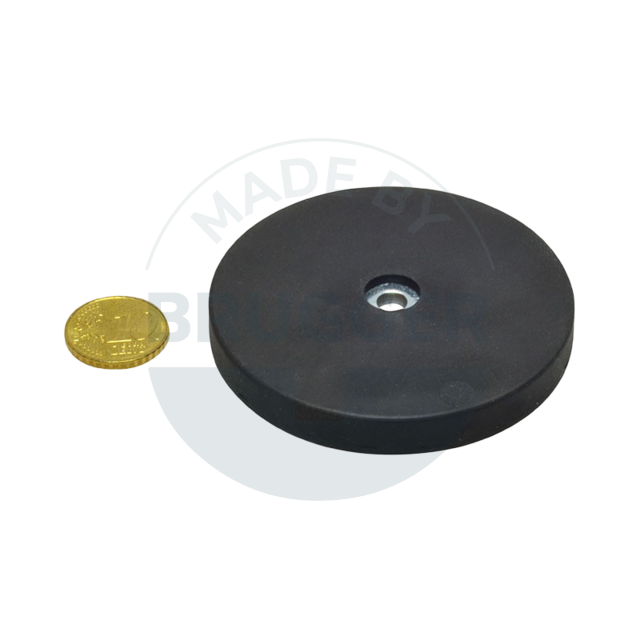

Rubberised magnet systems

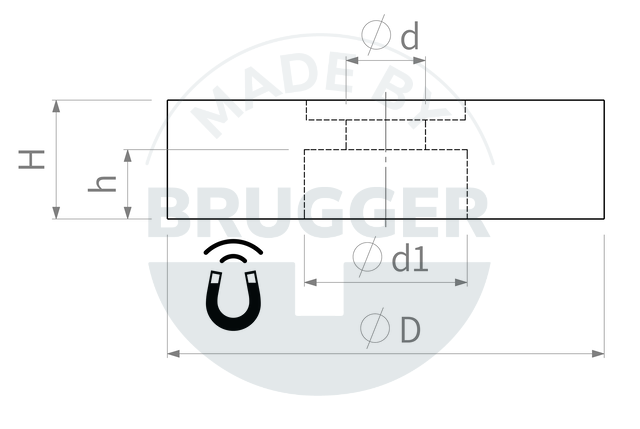

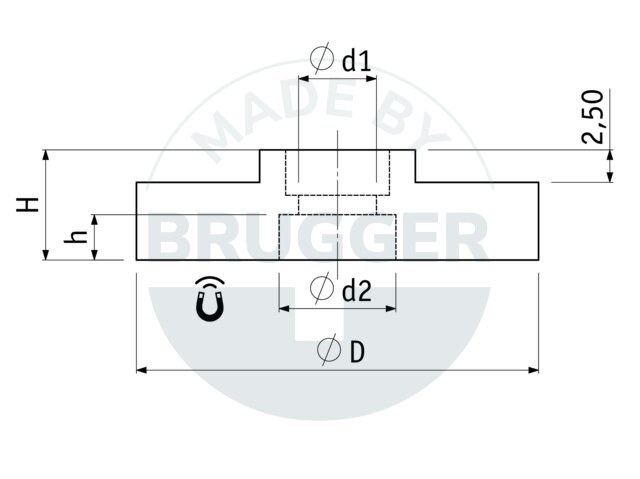

NdFeB magnetic system, black rubber sheath, with cylinder bore

PRODUCT INFORMATION:

Sensitive surfaces can be optimally protected with rubberised magnetic systems. The special black rubber layer protects the surface from abrasion or scratches and at the same time increases the adhesive strength under lateral load. This round magnetic system has a cylindrical hole and can be attached with a screw without countersinking.

As an alternative to the standard version, we also offer customised solutions:

" Other colours for the rubber coating

" Harder or softer rubber coating

* The forces have been determined at room temperature on a polished plate made of steel (S235JR according to DIN 10 025) with a thickness of 10 mm (1kg~10N). A deviation of up to -10% from the specified value is possible in exceptional cases. In general, the value is exceeded. The type of application (installation situation, temperatures, counter anchors, etc.) sometimes influence the forces enormously. The values given are for orientation purposes. Let our experts advise you.