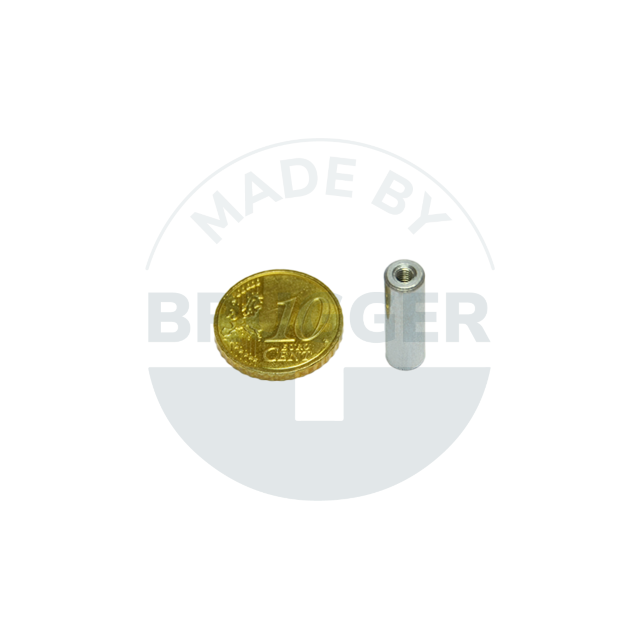

S6G 6 +0.1 /-0.1 20 +0.2 /-0.2 M3x5 2 4 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

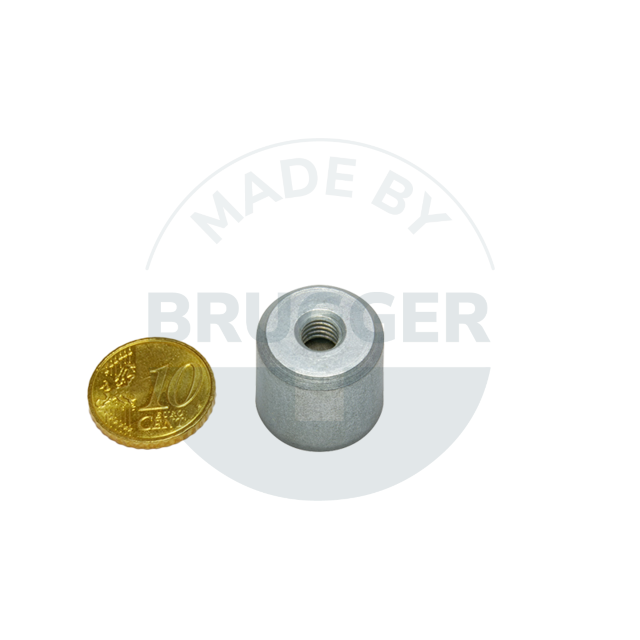

S6G

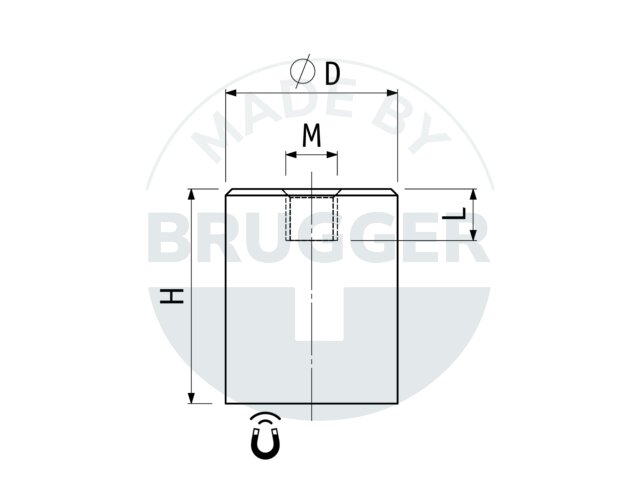

D mm:

6 +0.1 /-0.1

H mm:

20 +0.2 /-0.2

Thread MxL:

M3x5

Adhesive force* N:

2

Weight g:

4

Temperature °C:

450

S12.5 12.5 +0.1 /-0.1 16 +0.2 /-0.2 M4x6 20 15 350

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S12.5

D mm:

12.5 +0.1 /-0.1

H mm:

16 +0.2 /-0.2

Thread MxL:

M4x6

Adhesive force* N:

20

Weight g:

15

Temperature °C:

350

S8G 8 +0.1 /-0.1 20 +0.2 /-0.2 M3x5 4 7.5 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

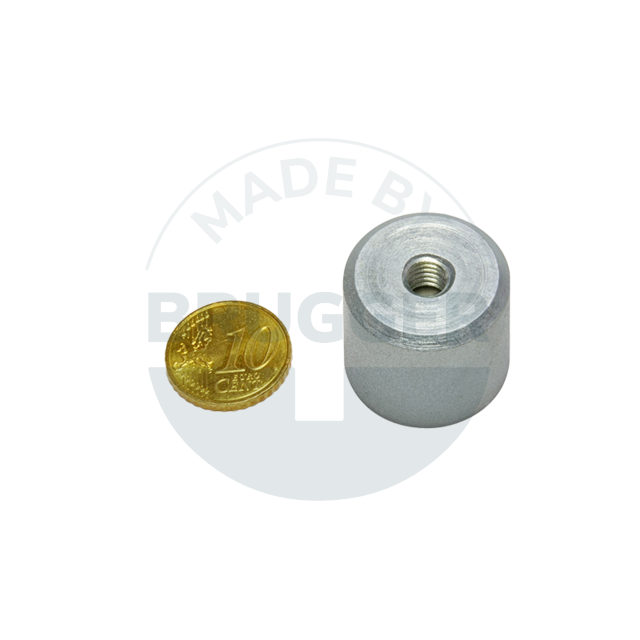

S8G

D mm:

8 +0.1 /-0.1

H mm:

20 +0.2 /-0.2

Thread MxL:

M3x5

Adhesive force* N:

4

Weight g:

7.5

Temperature °C:

450

S10G 10 +0.1 /-0.1 20 +0.2 /-0.2 M4x7 8.5 11 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S10G

D mm:

10 +0.1 /-0.1

H mm:

20 +0.2 /-0.2

Thread MxL:

M4x7

Adhesive force* N:

8.5

Weight g:

11

Temperature °C:

450

S17 17 +0.2 /-0.2 16 +0.2 /-0.2 M6x5 26 29 350

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S17

D mm:

17 +0.2 /-0.2

H mm:

16 +0.2 /-0.2

Thread MxL:

M6x5

Adhesive force* N:

26

Weight g:

29

Temperature °C:

350

S13G 13 +0.1 /-0.1 20 +0.2 /-0.2 M4x7 12 19 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S13G

D mm:

13 +0.1 /-0.1

H mm:

20 +0.2 /-0.2

Thread MxL:

M4x7

Adhesive force* N:

12

Weight g:

19

Temperature °C:

450

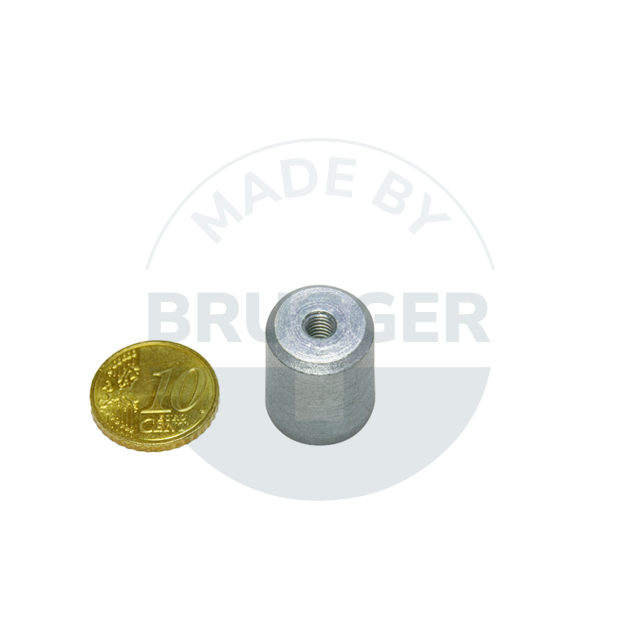

S16G 16 +0.1 /-0.1 20 +0.2 /-0.2 M4x5 20 30 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S16G

D mm:

16 +0.1 /-0.1

H mm:

20 +0.2 /-0.2

Thread MxL:

M4x5

Adhesive force* N:

20

Weight g:

30

Temperature °C:

450

S20G 20 +0.1 /-0.1 25 +0.2 /-0.2 M6x7 40 55 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

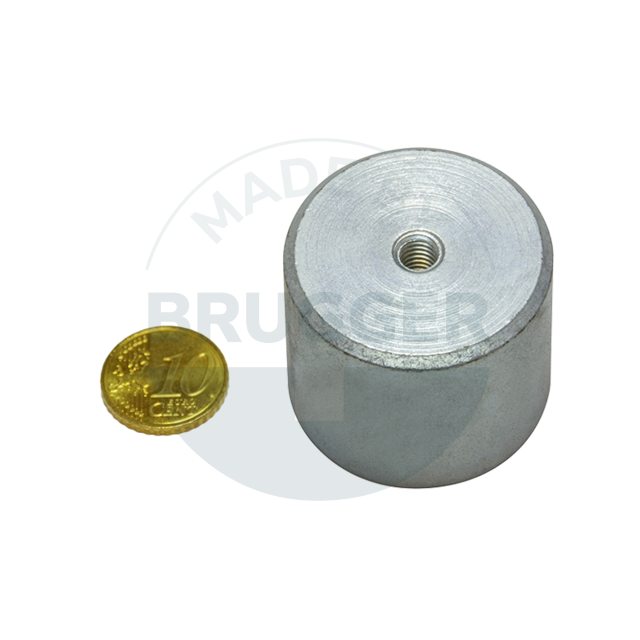

S20G

D mm:

20 +0.1 /-0.1

H mm:

25 +0.2 /-0.2

Thread MxL:

M6x7

Adhesive force* N:

40

Weight g:

55

Temperature °C:

450

S21 21 +0.1 /-0.1 19 +0.2 /-0.2 M6x7 40 50 350

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S21

D mm:

21 +0.1 /-0.1

H mm:

19 +0.2 /-0.2

Thread MxL:

M6x7

Adhesive force* N:

40

Weight g:

50

Temperature °C:

350

S27 27 +0.1 /-0.1 25 +0.2 /-0.2 M6x8 65 98 350

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S27

D mm:

27 +0.1 /-0.1

H mm:

25 +0.2 /-0.2

Thread MxL:

M6x8

Adhesive force* N:

65

Weight g:

98

Temperature °C:

350

S25G 25 +0.1 /-0.1 35 +0.2 /-0.2 M6x9 60 121 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S25G

D mm:

25 +0.1 /-0.1

H mm:

35 +0.2 /-0.2

Thread MxL:

M6x9

Adhesive force* N:

60

Weight g:

121

Temperature °C:

450

S32G 32 +0.1 /-0.1 40 +0.2 /-0.2 M8x9 160 220 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S32G

D mm:

32 +0.1 /-0.1

H mm:

40 +0.2 /-0.2

Thread MxL:

M8x9

Adhesive force* N:

160

Weight g:

220

Temperature °C:

450

S40G 40 +0.2 /-0.1 50 +0.2 /-0.2 M8x12 240 436 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S40G

D mm:

40 +0.2 /-0.1

H mm:

50 +0.2 /-0.2

Thread MxL:

M8x12

Adhesive force* N:

240

Weight g:

436

Temperature °C:

450

S35 35 +0.1 /-0.1 30 +0.2 /-0.2 M6x9 150 205 350

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S35

D mm:

35 +0.1 /-0.1

H mm:

30 +0.2 /-0.2

Thread MxL:

M6x9

Adhesive force* N:

150

Weight g:

205

Temperature °C:

350

S50G 50 +0.3 /-0.1 60 +0.2 /-0.2 M10x12 400 794 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S50G

D mm:

50 +0.3 /-0.1

H mm:

60 +0.2 /-0.2

Thread MxL:

M10x12

Adhesive force* N:

400

Weight g:

794

Temperature °C:

450

S63G 63 +0.3 /-0.1 65 +0.2 /-0.2 M12x14 660 1,274 450

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

S63G

D mm:

63 +0.3 /-0.1

H mm:

65 +0.2 /-0.2

Thread MxL:

M12x14

Adhesive force* N:

660

Weight g:

1,274

Temperature °C:

450