F10A-vM3 10 +0.1 /-0.1 6 +0.1 /-0.1 4,5 +0.2 /-0.1 11,5+0.3 /-0.2 M3 4 3 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

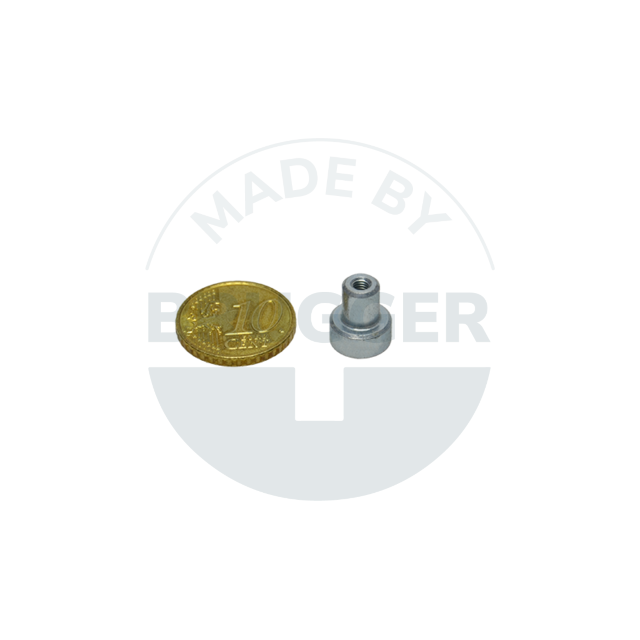

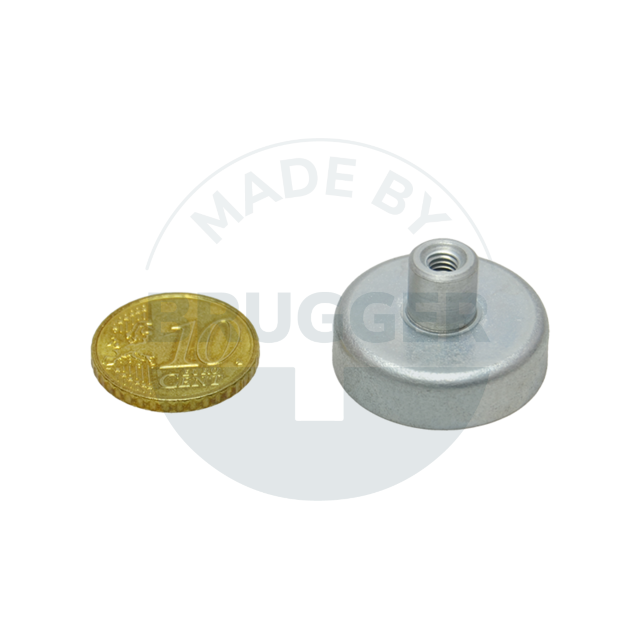

Article number:

F10A-vM3

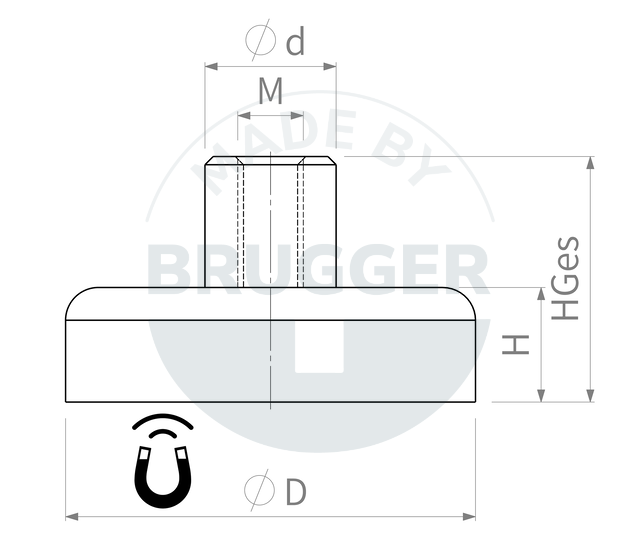

D mm:

10 +0.1 /-0.1

d mm:

6 +0.1 /-0.1

H mm:

4,5 +0.2 /-0.1

HGes mm:

11,5+0.3 /-0.2

M:

M3

Adhesive force* N:

4

Weight g:

3

Temperature °C:

200

F13A-vM3 13 +0.1 /-0.1 6 +0.1 /-0.1 4,5 +0.2 /-0.1 11,5+0.3 /-0.2 M3 10 4 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

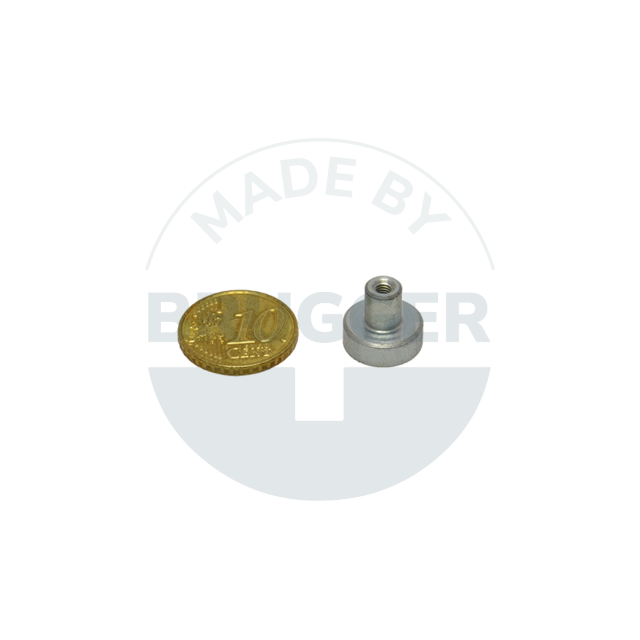

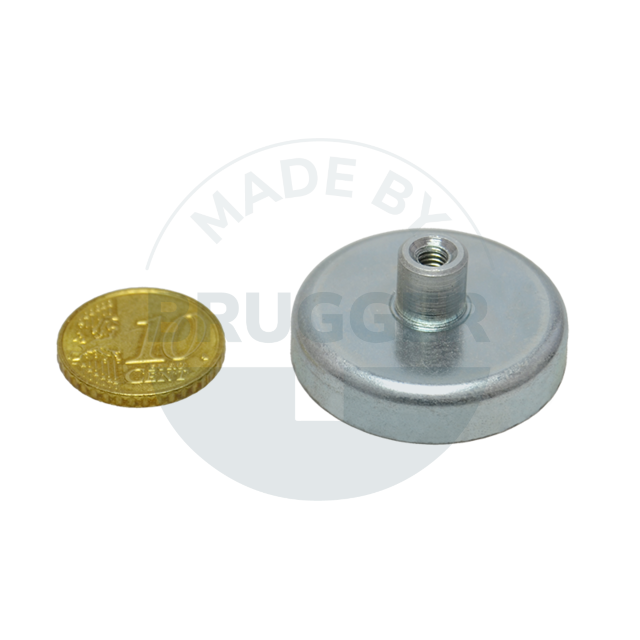

Article number:

F13A-vM3

D mm:

13 +0.1 /-0.1

d mm:

6 +0.1 /-0.1

H mm:

4,5 +0.2 /-0.1

HGes mm:

11,5+0.3 /-0.2

M:

M3

Adhesive force* N:

10

Weight g:

4

Temperature °C:

200

F16A-vM3 16 +0.1 /-0.1 6 +0.1 /-0.1 4,5 +0.2 /-0.1 11,5+0.3 /-0.2 M3 18 6 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

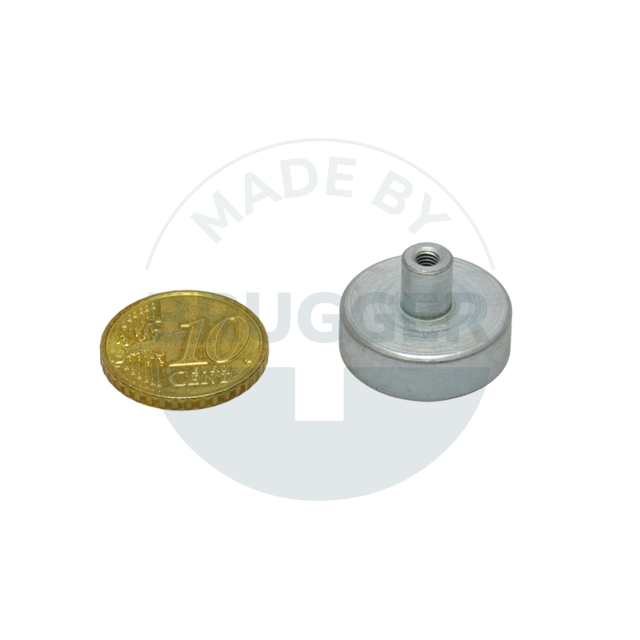

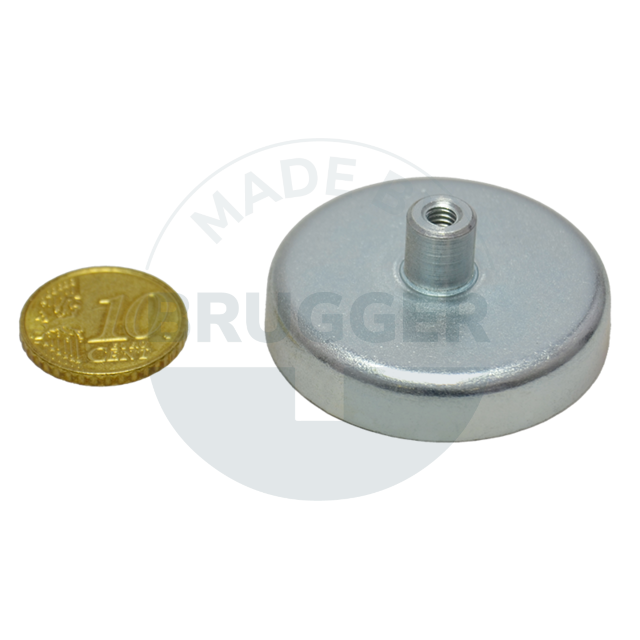

Article number:

F16A-vM3

D mm:

16 +0.1 /-0.1

d mm:

6 +0.1 /-0.1

H mm:

4,5 +0.2 /-0.1

HGes mm:

11,5+0.3 /-0.2

M:

M3

Adhesive force* N:

18

Weight g:

6

Temperature °C:

200

F20A-vM3 20 +0.1 /-0.1 6 +0.1 /-0.1 6 +0.2 /-0.1 13+0.3 /-0.2 M3 30 11 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

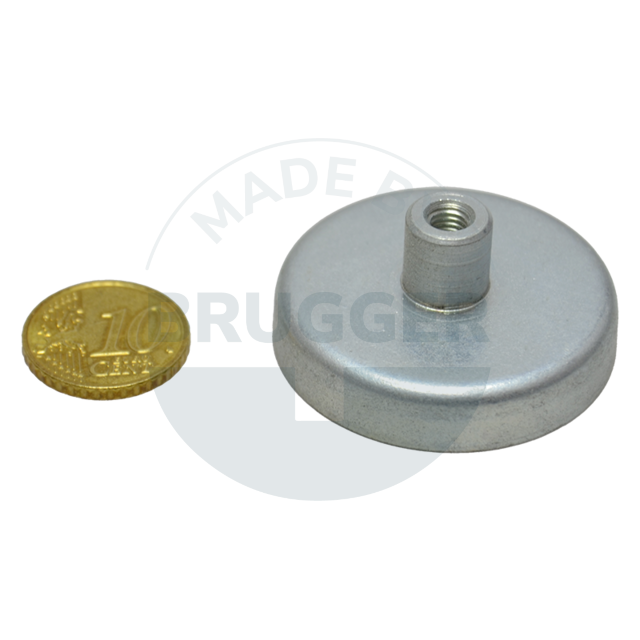

Article number:

F20A-vM3

D mm:

20 +0.1 /-0.1

d mm:

6 +0.1 /-0.1

H mm:

6 +0.2 /-0.1

HGes mm:

13+0.3 /-0.2

M:

M3

Adhesive force* N:

30

Weight g:

11

Temperature °C:

200

F25A-vM4 25 +0.1 /-0.1 8 +0.2 /-0.2 7 +0.3 /-0.2 15+0.5 /-0.3 M4 40 20 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F25A-vM4

D mm:

25 +0.1 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

7 +0.3 /-0.2

HGes mm:

15+0.5 /-0.3

M:

M4

Adhesive force* N:

40

Weight g:

20

Temperature °C:

200

F32A-vM4 32 +0.1 /-0.1 8 +0.2 /-0.2 7 +0.3 /-0.2 15+0.5 /-0.3 M4 80 31 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F32A-vM4

D mm:

32 +0.1 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

7 +0.3 /-0.2

HGes mm:

15+0.5 /-0.3

M:

M4

Adhesive force* N:

80

Weight g:

31

Temperature °C:

200

F36A-vM4 36 +0.2 /-0.1 8 +0.2 /-0.2 7,7 +0.3 /-0.2 16+0.5 /-0.3 M4 100 42 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F36A-vM4

D mm:

36 +0.2 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

7,7 +0.3 /-0.2

HGes mm:

16+0.5 /-0.3

M:

M4

Adhesive force* N:

100

Weight g:

42

Temperature °C:

200

F40A-vM4 40 +0.2 /-0.1 8 +0.2 /-0.2 8 +0.3 /-0.2 16,5+0.5 /-0.3 M4 125 57 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F40A-vM4

D mm:

40 +0.2 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

8 +0.3 /-0.2

HGes mm:

16,5+0.5 /-0.3

M:

M4

Adhesive force* N:

125

Weight g:

57

Temperature °C:

200

F40A-vM5 40 +0.2 /-0.1 10 +0.2 /-0.2 8 +0.3 /-0.2 18+0.5 /-0.3 M5 125 59 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F40A-vM5

D mm:

40 +0.2 /-0.1

d mm:

10 +0.2 /-0.2

H mm:

8 +0.3 /-0.2

HGes mm:

18+0.5 /-0.3

M:

M5

Adhesive force* N:

125

Weight g:

59

Temperature °C:

200

F47A-vM4 47 +0.2 /-0.1 8 +0.2 /-0.2 9 +0.4 /-0.2 17+0.6 /-0.3 M4 180 86 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F47A-vM4

D mm:

47 +0.2 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

9 +0.4 /-0.2

HGes mm:

17+0.6 /-0.3

M:

M4

Adhesive force* N:

180

Weight g:

86

Temperature °C:

200

F47A-vM6 47 +0.2 /-0.1 12 +0.2 /-0.2 9 +0.4 /-0.2 20,5+0.6 /-0.3 M6 180 91 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F47A-vM6

D mm:

47 +0.2 /-0.1

d mm:

12 +0.2 /-0.2

H mm:

9 +0.4 /-0.2

HGes mm:

20,5+0.6 /-0.3

M:

M6

Adhesive force* N:

180

Weight g:

91

Temperature °C:

200

F50A-vM4 50 +0.2 /-0.1 8 +0.2 /-0.2 10 +0.4 /-0.2 18,5+0.6 /-0.3 M4 220 105 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F50A-vM4

D mm:

50 +0.2 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

10 +0.4 /-0.2

HGes mm:

18,5+0.6 /-0.3

M:

M4

Adhesive force* N:

220

Weight g:

105

Temperature °C:

200

F50A-vM6 50 +0.2 /-0.1 12 +0.2 /-0.2 10 +0.4 /-0.2 22+0.6 /-0.3 M6 220 111 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F50A-vM6

D mm:

50 +0.2 /-0.1

d mm:

12 +0.2 /-0.2

H mm:

10 +0.4 /-0.2

HGes mm:

22+0.6 /-0.3

M:

M6

Adhesive force* N:

220

Weight g:

111

Temperature °C:

200

F57A-vM4 57 +0.2 /-0.1 8 +0.2 /-0.2 10,5 +0.5 /-0.2 18,5+0.7 /-0.3 M4 280 147 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F57A-vM4

D mm:

57 +0.2 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

10,5 +0.5 /-0.2

HGes mm:

18,5+0.7 /-0.3

M:

M4

Adhesive force* N:

280

Weight g:

147

Temperature °C:

200

F57A-vM6 57 +0.2 /-0.1 12 +0.2 /-0.2 10,5 +0.5 /-0.2 22,5+0.7 /-0.3 M6 280 153 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F57A-vM6

D mm:

57 +0.2 /-0.1

d mm:

12 +0.2 /-0.2

H mm:

10,5 +0.5 /-0.2

HGes mm:

22,5+0.7 /-0.3

M:

M6

Adhesive force* N:

280

Weight g:

153

Temperature °C:

200

F63A-vM4 63 +0.3 /-0.1 8 +0.2 /-0.2 14 +0.5 /-0.2 22+0.7 /-0.3 M4 350 228 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F63A-vM4

D mm:

63 +0.3 /-0.1

d mm:

8 +0.2 /-0.2

H mm:

14 +0.5 /-0.2

HGes mm:

22+0.7 /-0.3

M:

M4

Adhesive force* N:

350

Weight g:

228

Temperature °C:

200

F63A-vM8 63 +0.3 /-0.1 15 +0.2 /-0.2 14 +0.5 /-0.2 30+0.7 /-0.3 M8 350 245 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F63A-vM8

D mm:

63 +0.3 /-0.1

d mm:

15 +0.2 /-0.2

H mm:

14 +0.5 /-0.2

HGes mm:

30+0.7 /-0.3

M:

M8

Adhesive force* N:

350

Weight g:

245

Temperature °C:

200

F80A-vM6 80 +0.3 /-0.1 12 +0.2 /-0.2 18 +0.5 /-0.2 28,5+0.7 /-0.3 M6 600 477 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F80A-vM6

D mm:

80 +0.3 /-0.1

d mm:

12 +0.2 /-0.2

H mm:

18 +0.5 /-0.2

HGes mm:

28,5+0.7 /-0.3

M:

M6

Adhesive force* N:

600

Weight g:

477

Temperature °C:

200

FG080HFA-06v-00 80 +0.3 /-0.1 12 +0.2 /-0.2 10 +0.5 /-0.2 21,5+0.7 /-0.3 M6 600 273 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

FG080HFA-06v-00

D mm:

80 +0.3 /-0.1

d mm:

12 +0.2 /-0.2

H mm:

10 +0.5 /-0.2

HGes mm:

21,5+0.7 /-0.3

M:

M6

Adhesive force* N:

600

Weight g:

273

Temperature °C:

200

F80A-vM10 80 +0.3 /-0.1 20 +0.2 /-0.2 18 +0.5 /-0.2 34+0.7 /-0.3 M10 600 499 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F80A-vM10

D mm:

80 +0.3 /-0.1

d mm:

20 +0.2 /-0.2

H mm:

18 +0.5 /-0.2

HGes mm:

34+0.7 /-0.3

M:

M10

Adhesive force* N:

600

Weight g:

499

Temperature °C:

200

F100A-vM12 100 +0.5 /-0.1 22 +0.2 /-0.2 22 +0.5 /-0.2 43+0.7 /-0.3 M12 900 956 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F100A-vM12

D mm:

100 +0.5 /-0.1

d mm:

22 +0.2 /-0.2

H mm:

22 +0.5 /-0.2

HGes mm:

43+0.7 /-0.3

M:

M12

Adhesive force* N:

900

Weight g:

956

Temperature °C:

200

F125A-vM14 125 +0.5 /-0.1 25 +0.2 /-0.2 26 +0.5 /-0.2 50+0.7 /-0.3 M14 1,300 1,720 200

Bookmark variant for price request

Remove variant from price request

Download CAD file

Show item image and description

Article number:

F125A-vM14

D mm:

125 +0.5 /-0.1

d mm:

25 +0.2 /-0.2

H mm:

26 +0.5 /-0.2

HGes mm:

50+0.7 /-0.3

M:

M14

Adhesive force* N:

1,300

Weight g:

1,720

Temperature °C:

200