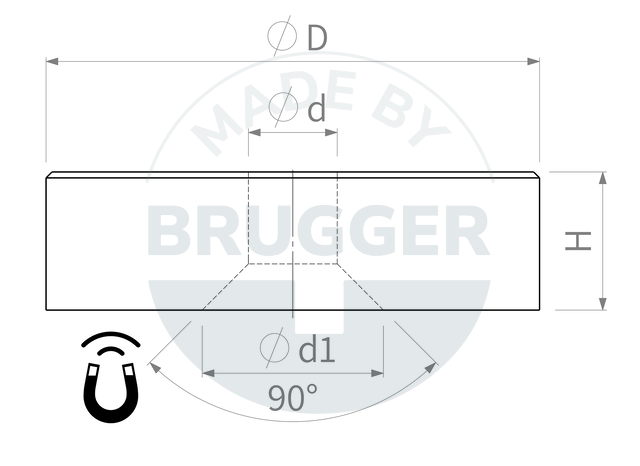

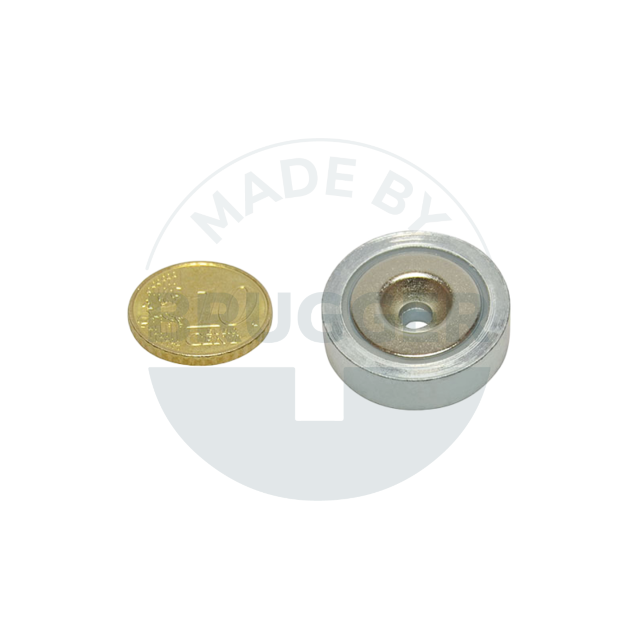

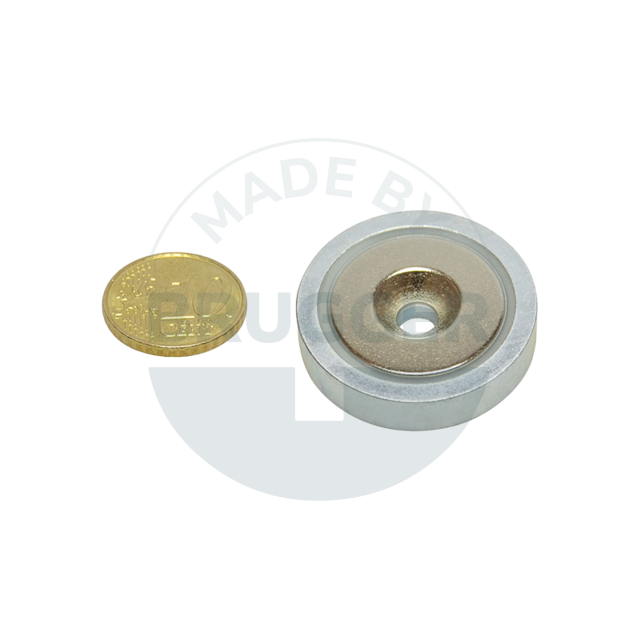

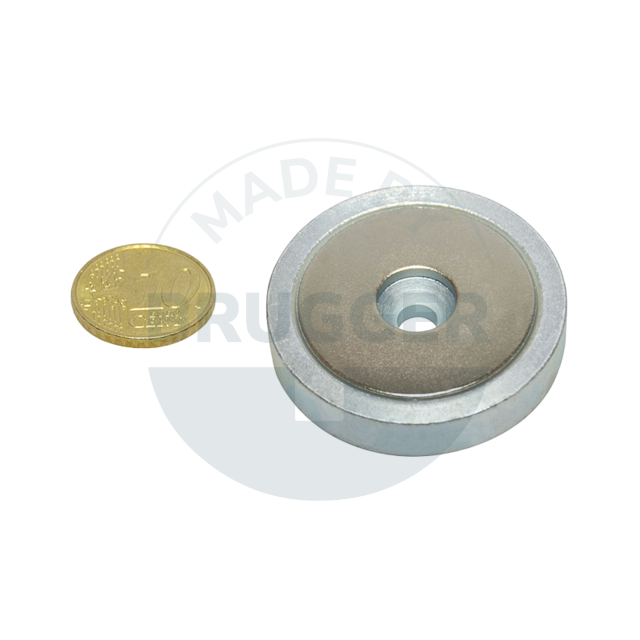

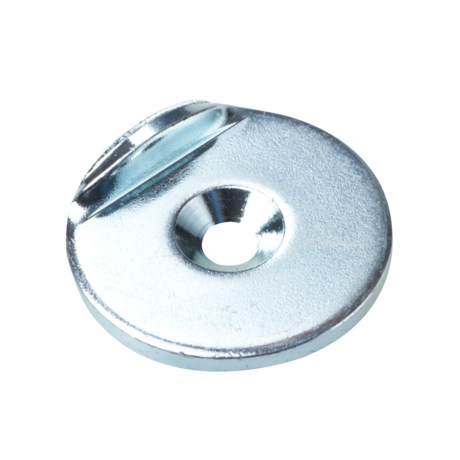

Flat pot magnets of Neodymium-iron-boron (NdFeB)

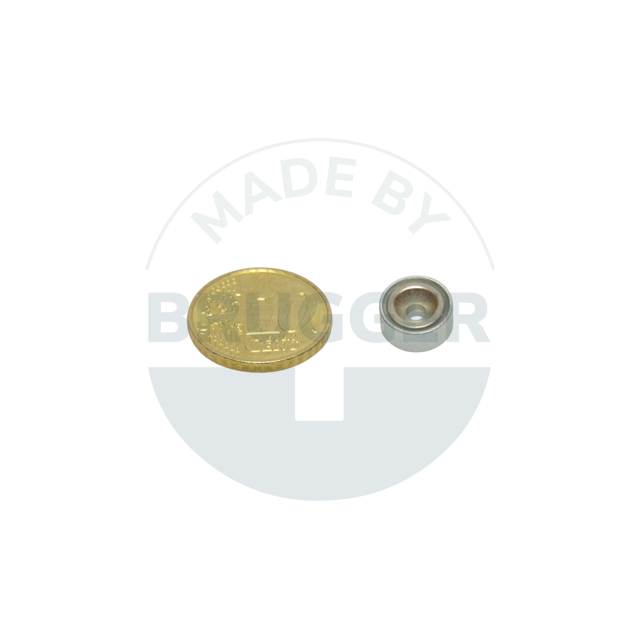

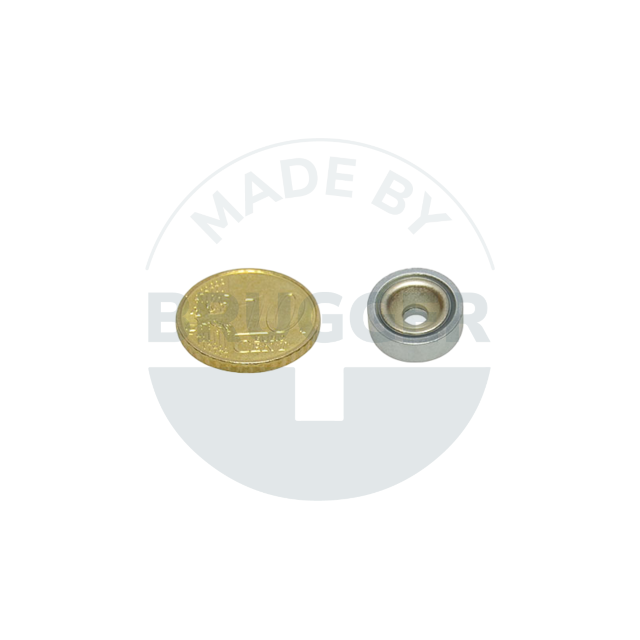

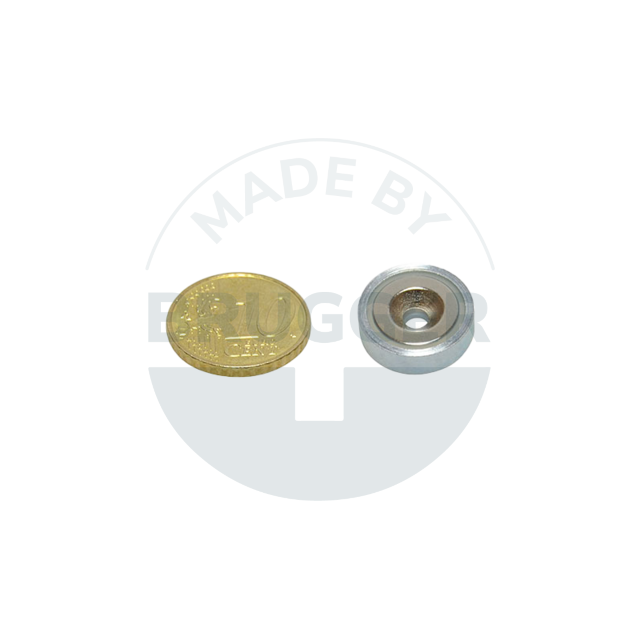

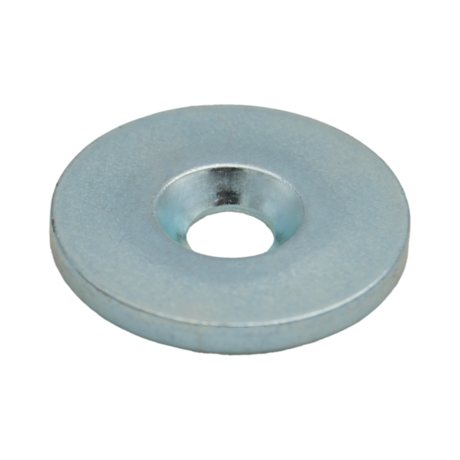

Pot magnets made of NdFeB, steel housing, with hole and countersink, galvanised

PRODUCT INFORMATION:

Pot magnets use a galvanised metal pot to maximise their adhesive force. The magnetic core is located inside the pot, leaving the holding surface free. By redirecting the magnetic flux through the pot, the force is significantly increased. This enables even small magnets to develop a surprising holding force. The versatile uses of pot magnets range from industrial applications, where they serve as gripper magnets for transporting metal parts (in this variant with bore and countersink), to numerous other applications.

As an alternative to the standard version, we also offer customised solutions:

" Black galvanised surface for housing, resulting in higher corrosion resistance (up to 720 hours in a salt spray test - depending on the magnet material)

* The forces have been determined at room temperature on a polished plate made of steel (S235JR according to DIN 10 025) with a thickness of 10 mm (1kg~10N). A deviation of up to -10% from the specified value is possible in exceptional cases. In general, the value is exceeded. The type of application (installation situation, temperatures, counter anchors, etc.) sometimes influence the forces enormously. The values given are for orientation purposes. Let our experts advise you.