Neodymium magnets (NdFeB): Maximum adhesive force for demanding applications

Neodymium magnets, also known assuper magnets, are among thestrongest permanent magnets in the world. Despite their compact size, they develop an enormously high magnetic holding force - magnets just a few millimetres in diameter can hold several kilograms of weight. This makes neodymium magnets the first choice in many areas of industry, trade and everyday life.

Neodymium magnets - The most powerful magnets in the world

Neodymium belongs to the group of so-calledrare earthsand is one of the most important elements for the production ofpowerful permanent magnets. In combination with iron and boron, it produces the powerful alloy neodymium-iron-boron (NdFeB) - the basis for thestrongest permanent magnets in the world.

The amount of material used per magnet is very efficient - the quantity used is small compared to the benefits (high holding force, compact design, long service life).

At BRUGGER, we pay attention to sustainable procurement and efficient utilisation of materials. With ourFairMagnetinitiative, we promote compliance with ecological, social and economic standards along the entire supply chain at our suppliers in China. The aim is sustainable magnet production under fair working conditions and with active environmental protection.

Neodymium - key raw material for modern high-performance magnets

Neodymium magnets impress with their exceptionally high magnetic energy and compact size. Despite their small dimensions, they can hold many times their own weight - a property that makes them the ideal solution for numerous applications in technology, industry and everyday life.

Neodymium magnets can hold up to a hundred times their own weight- permanently. In wind turbines or electric motors, neodymium magnets increase energy efficiency and enable the expansion of renewable energies - an important step towards the energy transition. At BRUGGER, we also build special systems for the wind power industry, some of which weigh several hundred kilograms.

Properties of neodymium magnets:

- Extremely high magnetic flux density for maximum holding force

- Space-saving & powerful - ideal for compact applications

- Temperature dependency: Loss of magnetic force at high temperatures - therefore usually provided with protective coatings

- Corrosion protection: To prevent oxidation, neodymium magnets are often nickel-plated, galvanised or otherwise coated or sheathed.

Areas of application for neodymium magnets:

Thanks to their strength and reliability, neodymium magnets have become indispensable in many industries:

- Electric motors & generators - crucial for electric vehicles, robotics and drive technology

- Wind turbines - improve the energy efficiency and operational reliability of turbines

- Electronics - in loudspeakers, headphones, smartphones and hard drives for high-performance miniature solutions

- Medical technology - in high-tech devices such as MRI scanners for precise diagnostics

- Industry & mechanical engineering - for sensor systems, mounts, filter technology and automated processes

- DIY & hobby - popular for creative applications, furniture making, prototyping or construction toys

Acting responsibly with FairMagnet

As neodymium magnets are currently produced almost exclusively in China, we promote compliance with ecological, economic and social standards throughout the entire supply chain with our FairMagnet initiative. Sustainability, environmental protection and fair working conditions are a matter of course for us - from the selection of raw materials to the finished product. Neodymium magnets are currently not subject to such strict export restrictions from China as other, more critical rare earths (such as dysprosium, terbium or europium-containing phosphors). Although a large proportion of global neodymium production comes from China, the material is both globally available and easily recyclable, which further reduces dependency.

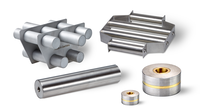

Our various neodymium magnet systems for a wide range of applications

Did you know? All key processes take place at our site in Hardt. BRUGGER has a modern machine park with over 1000 tools and devices. Over 9 million magnet systems "Made in Germany" leave our production facility every year. An extensive stock of standard products allows us to process orders quickly and flexibly.

Customised neodymium magnet solutions for industry & technology

Do you have special requirements? Our experts will advise you personally and develop customised magnet solutions for your exact area of application